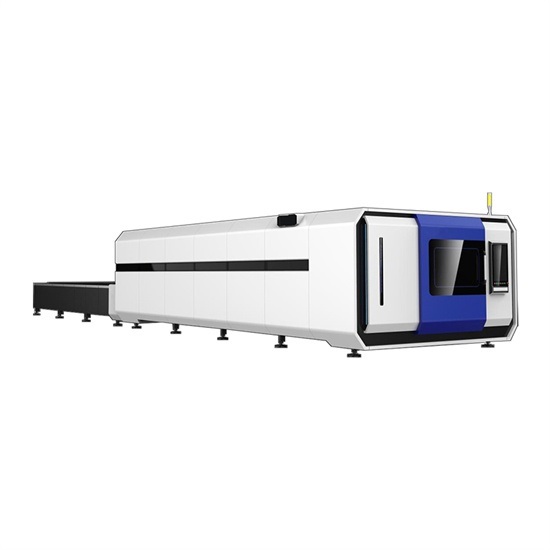

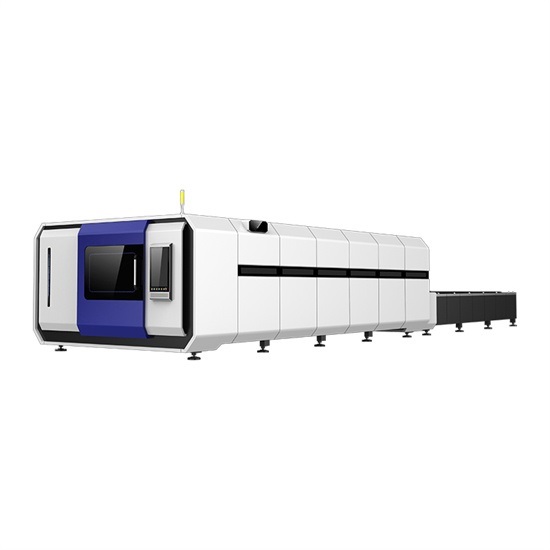

Fully Enclosed Laser Cutting Machines

Details:

Full Cover CNC Fiber Laser Cutting Machine For Stainless Steel Cutting Machines

Features

1. Full Cover CNC Fiber Laser Cutting Machine For Stainless Steel Cutting Machines cutting speed is fast, low operation and maintenance cost, and easy to learn.

2. The machine adopts the dynamic dragon door structure, gear rack and linear guide, and the transmission is stable, and the precision is high.

3. The machine tool and the beam pass high temperature, precision gantry, can maintain high strength, high precision, and long-term work is not deformable.

4. X, Y, Z axis use imported servo motors, high precision, high speed, large torque, high inertia, and stable and durable. The high speed and acceleration of the whole machine are guaranteed.

5. The special CNC system of Shanghai Bochu fiber laser cutting machine based on Windows operating system is integrated with laser cutting control dedicated function modules, powerful, human-machine interface, simple operation.

6. Full-enclosed structure, using professional radiation protection materials, to ensure the personal safety of the surrounding personnel.

Full protection and humanized design

Full Cover CNC Fiber Laser Cutting Machine For Stainless Steel Cutting Machines is fully enclosed laser protective glass design, prevents the laser from harming people. Automatic dust collection system, the cutting dust is internally filtered and discharged under certain standard, making the process more eco-friendly and no pollution. Intelligent monitoring system, real-time intelligent monitoring, reducing the incidence of accidents.

High-speed exchange table

High-speed parallel exchange table design, dual working table exchange at the same time, stable and reliable transmission mode. Fast, shorten the exchange time, save the loading and unloading auxiliary time. Exchange motor controlled by frequency converter, can finish the table exchange within 15S.

New "core" intelligent system

New generation of CNC system, more flexible in operation. Imported mature system and servo motors, integrated independently developed special laser cutting system. Operation system provides a rich and friendly human-computer interaction interface, which is a bridge for communication and interaction between machines and humans.

Auto focus laser cutting head , Automatic focusing

Full Cover CNC Fiber Laser Cutting Machine For Stainless Steel Cutting Machines Laser head with auto focus function, can adjust the focus automatically, don’t need to adjust by manual, The software can change different focusing lenses automatically and quickly to meet the cutting of different thickness plates, Simple, convenient, fast and accurate in operation.

Large adjustment range

The accuracy is 0.01mm, suitable for different types of 0-20mm plates.

Long life span

Full-circle water cooling around the focusing component, realizing high-power, small-volume and long-term cutting. No heat, no fog, improve the life of laser cutting head.

Cast aluminum gantry

Using low-pressure steel film casting process, the beam has high compactness, the surface quality of the beam is smooth, and the integrity and rigidity are excellent. At the same time, it has good toughness, ductility and corrosion resistance. Reduce the load of the servo motor, reduce the inertia, While saving electricity costs, it improves the operating speed of the equipment.

Truss beam type composite bed

Gantry structure, dual drive synchronous compensation technology, stable structure, good rigidity and high dynamic response. After overall annealing heat treatment, remove the welding stress, keep the machine bed from deforming during transportation and use. Guide rail surface of the bed, integrally processed by gantry machining center, flatness error of the installation surface is 0.02mm.

Application

Full Cover CNC Fiber Laser Cutting Machine For Stainless Steel Cutting Machines is widely used in: electric electrical, automotive manufacturing, mechanical equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising logo, automotive decoration, precision parts, chassis cabinets, furniture, lighting, process ornaments and other industries.

|

Main Configurations |

|||

|

Working area |

1500*3000mm |

Voltage |

380V 50HZ |

|

FiberLaser source |

Raycus/JPT/IPG/MAX |

Laser power |

1000w |

|

Control system |

Weihong/Bochu |

Laser head |

Asmit laser cutting head |

|

Control software |

Cypcut |

Rail guide |

Taiwan linear rail |

|

Motor and driver |

Japanese Servo |

Transmission |

Gear rack transmission from Taiwan |

|

Table |

Exchange table |

Cooling system |

Water chiller |

|

Parameters |

|||

|

Effective cutting width ( X axis ) |

1500mm |

Effective cutting length ( Y axis ) |

3000mm |

|

Type |

Fiber laser |

Power |

1000w - 12000w optional |

|

max.cutting speed |

40m/min |

fast moving speed |

80m/min |

|

Max.load of worktable |

500kg/㎡ |

X,Y axis max.acceleration |

1g |

|

Max Working area |

width: 1500 - 2500mm |

Weight of machine |

5.5Tons |

|

Motor |

Japanese servo motors |

Controller |

Weihong |

|

X,Y-axis positioning accuracy |

±0.02mm |

X,Y-axis repeat positioning accuracy |

±0.01mm |

|

Support software |

CYPCUT |

Graphic Format Supported |

DXF/AI |

Product list

- CNC Wood Router

- Fiber Laser Cutting Machines

- Sheet And Tube Laser Cutting Machines

- Fully Enclosed Laser Cutting Machines

- Laser Welding Machines

- Laser Cleaning Machines

- Laser Marking Machines

- > Fiber Laser Marking Machine

- > Co2 Laser Marking Machine

- CNC Plasma Cutting Machines

- > Table Plasma Cutting Machine

- > Portable Plasma Cutting Machine

- > Gantry Plasma Cutting Machine

- > Tube Plasma Cutting Machines

- Co2 Laser Machines

- > Non Metal Co2 Laser Cutting Machine

- > Metal Co2 Laser Cutting Machine

- UV Printer