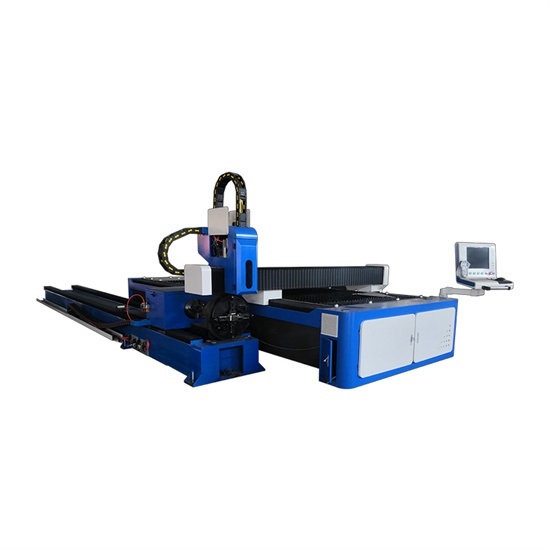

Sheet And Tube Laser Cutting Machines

Details:

Metal Sheet Pipes Fiber Laser Cutting Machines

Features

1. JNKEVO Metal Sheet Pipes Fiber Laser Cutting Machines cutting speed is fast, low operation and maintenance cost, and easy to learn.

2. The machine adopts the dynamic dragon door structure, gear rack and linear guide, and the transmission is stable, and the precision is high.

3. The machine tool and the beam pass high temperature, precision gantry, can maintain high strength, high precision, and long-term work is not deformable.

4. X, Y, Z axis use imported servo motors, high precision, high speed, large torque, high inertia, and stable and durable. The high speed and acceleration of the whole machine are guaranteed.

5. The special CNC system of Shanghai Bochu fiber laser cutting machine based on Windows operating system is integrated with laser cutting control dedicated function modules, powerful, human-machine interface, simple operation.

6. Front and rear dual drive automatic clamping card disc, automatic clamping, automatic centering, suitable for various specifications symmetric cross-section pipe.

Pneumatic chuck design

The front and rear chuck clamping design is convenient for installation, labor-saving, and no wear and tear. Ensure the stability of feeding and cutting accuracy; Automatic adjustment of the center, suitable for various pipes, high chuck rotation speed, can improve processing efficiency.

Aerospace aluminum gantry

The aerospace aluminum is manufactured under aerospace standards. After artificial aging and solution treatment, it is finished. Hardness can reach to T6, and it has the characteristics of good toughness and ductility.

Light in weight, convenient for high-speed movement during processing, and is highly flexible. It can greatly increase the processing speed when the accuracy is met.

Tube welding bed design

8MM steel pipe welded bed with stable structure and high temperature annealing treatment to eliminate the stress caused by welding and machining. Reduce the loss of laser cutting machine in use, no deformation after 30 years of use

Intelligent alarm system

Comprehensive abnormal alarm, which can be pushed to the interface through the control center to detect abnormalities in advance, Reduce hidden dangers and double the effect of equipment abnormality investigation.

Application

Metal Sheet Pipes Fiber Laser Cutting Machines is suitable for sheet metal processing, hardware parts, kitchen, advertising, machinery, decoration, car, gift, lamp, knife, medical equipment, sports equipment and other industries . Can be precision cutting stainless steel, carbon steel, alloy steel, alloy, galvanized plate, aluminum, copper, gold, silver, titanium (tube) (related to power).

|

Main Configurations |

|||

|

Working area |

1500*3000mm |

Voltage |

380V 50HZ |

|

FiberLaser source |

Raycus/JPT/IPG/MAX |

Laser power |

1000w |

|

Control system |

Weihong/Bochu |

Laser head |

Asmit laser cutting head |

|

Control software |

Cypcut |

Rail guide |

Taiwan linear rail |

|

Motor and driver |

Japanese Servo |

Transmission |

Gear rack transmission from Taiwan |

|

Table |

Exchange table |

Cooling system |

Water chiller |

|

Parameters |

|||

|

Effective cutting width ( X axis ) |

1500mm |

Effective cutting length ( Y axis ) |

3000mm |

|

Type |

Fiber laser |

Power |

1000w - 12000w optional |

|

max.cutting speed |

40m/min |

fast moving speed |

80m/min |

|

Max.load of worktable |

500kg/㎡ |

X,Y axis max.acceleration |

1g |

|

Max sheet cutting size |

width: 1500 - 2500mm |

Max tube cutting size |

diameter: 20 - 320mm |

|

Motor |

Japanese servo motors |

Controller |

Weihong |

|

X,Y-axis positioning accuracy |

±0.02mm |

X,Y-axis repeat positioning accuracy |

±0.01mm |

|

Support software |

CYPCUT |

Graphic Format Supported |

DXF/AI |

Product list

- CNC Wood Router

- Fiber Laser Cutting Machines

- Sheet And Tube Laser Cutting Machines

- Fully Enclosed Laser Cutting Machines

- Laser Welding Machines

- Laser Cleaning Machines

- Laser Marking Machines

- > Fiber Laser Marking Machine

- > Co2 Laser Marking Machine

- CNC Plasma Cutting Machines

- > Table Plasma Cutting Machine

- > Portable Plasma Cutting Machine

- > Gantry Plasma Cutting Machine

- > Tube Plasma Cutting Machines

- Co2 Laser Machines

- > Non Metal Co2 Laser Cutting Machine

- > Metal Co2 Laser Cutting Machine

- UV Printer